Type B

(Integral protection)

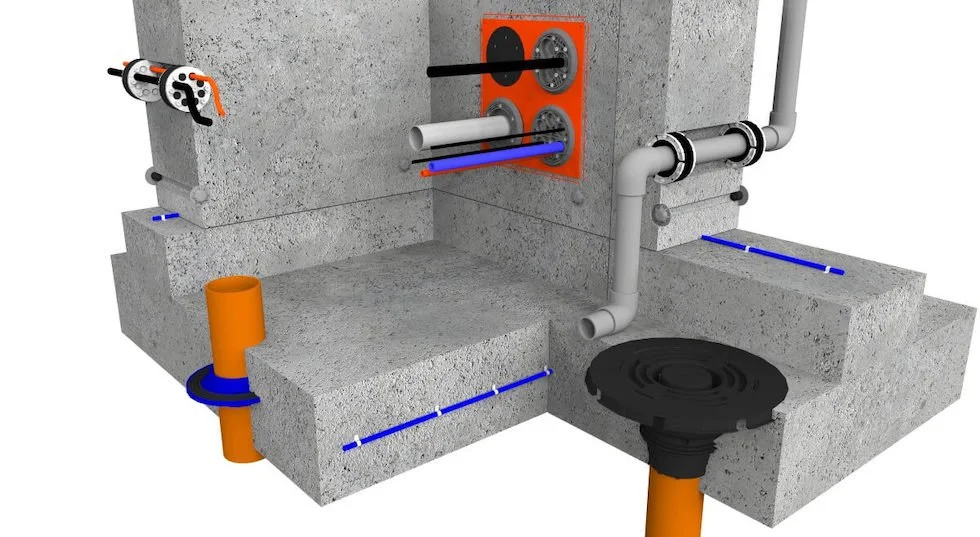

Type B protection refers to a waterproofing strategy where the structure itself is designed to be water-resistant, and is one of the three waterproofing types defined in BS 8102:2022 – Code of Practice for Protection of Below Ground Structures Against Water Ingress.

British Standard 8102:2022 defines Type B waterproofing as designing the structure itself to be integrally waterproof and the primary resistance to water ingress.

Nothing provides better primary resistance to water than a well-designed and well-placed reinforced concrete structure, designed in accordance with BS EN 1992 with sufficient steel reinforcement to limit flexural and sectional cracking and therefore produce watertight concrete elements.

The use of correctly designed and installed waterbars at the places where the concrete isn’t, such as at joints and penetrations, will result in a Type B structure that should be fully watertight.

Consideration to compliance with the New Zealand Building Codes, may include performance clauses such as:

B1 Structure: Performance Clauses B1.3.1, B1.3.2, B1.3.3 (a, b, f, h, m, q)

B1.3.4 B2 Durability: Performance clause B2.3.1-(a) not less than 50 years

F2 Hazardous Building Materials: Performance clause F2.3.1

-

Injectable Waterbars

High performance waterbar systems installed within and used for sealing construction joints in earth-retaining and water-retaining concrete structures.

When injected with injection resin, the material penetrates into the concrete surrounding the construction joint to permanently seal any cracks, capillaries, pores and honeycombing within the structure.

Systems can be installed to be reusable considering NZBC E2.3.7 Building elements constructed in a way that makes due allowance the consequences of failure.

When installed and injected correctly the addition of this system Improves the water tightness of the ‘Type B’ waterproof structure by sealing the joints and encouraging improvements in the quality of the concrete placement.

-

Hydrophilic Waterbar

Hydrophilic waterbars have high elasticity and high tensile strength, made from a polymer which swells when in contact with moisture. Ideal for sealing structures against water leaks to both cast-in-place concrete and precast construction joints.

The swelling is achieved through hydrophilic acrylate polymers, which are inseparably embedded within the butylene carrier material. This results in high elasticity and exceptional tensile strength, even when fully expanded within the joint.

Due to its high resistance to acids, alkalis and organic solutions, Waterbars can be used to seal joints where aggressive water is expected such as within sewage treatment plants, biogas plants and liquid waste holding tanks.

Newtons 315 Waterbar swells up to 9 times its original size when in contact with water. Waterbars are commonly used in most construction joints.

-

Metal Waterbar

For the internal, strip-form sealing of construction joints and crack-control joints for cast-in-place concrete or precast wall elements. Coated or uncoated metal water bars are fast becoming the product of choice. becoming. No delayed swells and no weather constraints Installed and instant. Suitable for all typical construction and crack-control joints: floor slab/ floor slab, floor slab /wall, wall/wall, wall/ceiling, ceiling/ ceiling.

Installation of these products is quick and easy with the waterbar fitted in place to the reinforcement steel with special clips so that after the placement of the concrete, the waterbar is fully embedded within the two adjoining elements, completely blocking the passage of water through the joint.

-

Sealing Systems

Newton Systems NZ and Newton Waterproofing Systems UK are a specialist trade partner with Hauff-Technik, one of Europe’s leading manufacturers of completely reliable sealing systems for cable, pipe and line entries. There products are guaranteed to provide absolute tightness against ground water and ground gases.

Penetrations passing through the wall of the basement structure are notoriously hard to seal and are often the main reason for water ingress into the structure.

Innovative seals from Hauff-Technik provides opportunity for reliable sealing of core drills or wall sleeves for one or a number of pipes. These range from closed seal inserts for first-time installation to split seal inserts for retrofit sealing of pipes that have already been laid.

-

RiveStop System

Efficient Tie-Bolt Hole Sealing: The RiveStop system offers a unique and patented method for sealing tie-bolt holes in concrete walls, delivering significant time and cost savings compared to alternative mortars.

Simple Three-Element System: Comprising RivePipe, RiveOut, and RiveStop, the system provides a removable, reusable formwork tube, a manual extraction tool for quick tube removal, and a patented rivet system for hermetic sealing of tie-bolt holes.

Massive Time and Cost Savings: With savings of up to 90% in man-hours and material costs compared to other alternatives, RiveStop offers an efficient and cost-effective solution for tie-bolt hole sealing.